|

| Film industries ribbon mics |

When describing ribbon mics on this blog, I often note the output impedance of the mic, and possibly the transformer ratio too. Occasionally I receive messages asking how the impedance relates to output level, so here I will try to outline the role that the transformer plays in a ribbon mic. A ribbon mics is a very simple device, and if we consider how it works we will see just how important the transformer is.

In the beginning…. Let there be mics!

|

| Tannoy mic – ribbon, magnets and transformer |

In the early days of sound recording with ribbon mics, the destination would usually have been a tape recorder of some kind, with a tube preamplifier to receive and boost the signal from the microphone.

The mic could be connected in two ways: the budget option would be a high impedance connection using an unbalanced screened cable through a capacitor and straight to the tube grid, just like a guitar! The drawback is that unbalanced, high impedance connections are prone to picking up noise, and parasitic capacitance will limit the length of cable that can be used before the higher frequencies become significantly attenuated.

|

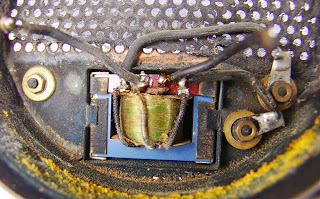

| Film Industries transformer dissected |

This Is The Modern World

Over the decades, broadcast and recording equipment has become more standardised, and most modern mixing desks and dedicated mic preamps are made to work well with microphones of up to around 600 ohms.

Ribbon microphones tend to have low outputs compared to modern dynamic and condenser mics, so it is advantageous to squeeze out as much level as we can. So, let’s go back to the transformer in our imaginary ribbon mic and re-design it for use in the today’s recording environment. We can keep the same primary winding, but change the secondary winding to one with a higher turns ratio.

|

| Xaudia ribbon mic transformers being assembled |

Let’s make it a 1:32 transformer, so now we need to take our 0.3 ohms from the ribbon and primary winding and multiply it by 32 squared, which gives 307 ohms. Once again we need to add the resistance from the secondary winding – in this case the wire is not only longer from the extra number of turns, and also will be thinner because we have squeezed the extra turns into the same space. A typical value would be 20 ohms, which would give us 327 ohms altogether, which most modern preamps can cope with quite happily.

Our output level will now be 32 mV, or 30dB gain with respect to 1 mV. So we have an improvement of +10dB over the 32 ohm transformer.

No Free Lunch

In life, and in physics, we know that you don’t get something for nothing. So are there any drawbacks with increasing the ratio. The higher impedance can increase the resistance noise, so it is important to make sure that the transformer is well designed with a very low DC resistance, particularly for the primary winding. However, the extra 10dB could be the difference between asking 50 dB gain from the preamp, or cranking it up 60 dB gain, where many preamps are becoming noisy.

Ancient and Modern

In most cases, it is worth getting the transformer right and demanding a bit less from the preamp. With vintage ribbon microphones it is very often possible to re-wind the original transformer to a higher ratio to get more output from the microphone. If the original laminations and winding style is used, the vintage tone of the mic can be retained, and overall this can give a stronger signal and a better signal-to-noise ratio into modern equipment.

|

| Vintage Ferrograph and Wearite matching transformers |

Another option is to use an impedance matching transformer. Back in the 1950s and 60s, most manufacturers of ribbon mics sold transformers to solve all kinds of matching problems. One example is this line matching transformer from Reslo, which connects a low impedance mic to a high impedance tape recorder. Xaudia make impedance matching transformer boxes with XLR fittings to do exactly the same job in a modern studio.

In part 2 of these ramblings I will discuss the effects of the transformer’s inductance and resistance characteristics.