I have no idea who made October’s microphone of the month. But it is quite a beast, dwarfing the SM57 that I have used as a geologist’s hammer*.

|

| Italian ribbon microphone by an unknown maker |

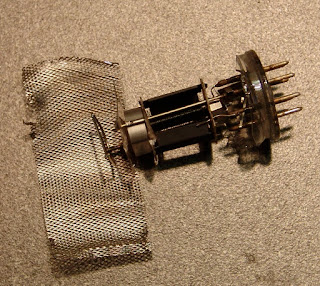

This one came from Italian ebay, and has a whiff of DIY about it. Except that if it is, the work quality is very high. It could well have been a project for an engineering degree. Or perhaps a prototype from a professional workshop? Some parts of the mic are well thought out, but ultimately it is let down by the transformer and low magnetic field.

The microphone body is based around brass tubing with an imposing chromed grill and chromed bells at each end. The base is fitted with a (horrible) 4 pin CB-radio style plug. The yoke is nicely bent aluminium with a turned base and wingnuts.

|

| Italian ribbon mic – motor and magnets |

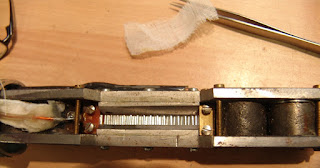

Inside, four large cylinder magnets are clamped between two heavy blocks of mild steel, and the ribbon motor sits at the centre. There is a hint of the RCA 44BX in this approach, and the ribbon is of similar dimensions to that mic. The ribbon itself is clamped with sturdy brass blocks. These magnets here are not really strong enough for the job and the measured field in the ribbon gap is around 1000 gauss – a bit low really. Perhaps they were once stronger than this.

The transformer has its own internal can for extra screening, and the connections to the tranny primary are made with heavy copper for very low resistance. Good thinking!

|

| Ribbon mic transformer |

The transformer itself looks home-made from recycled laminations. Although the thick copper wire for the primary is a sensible choice, the inductance is a rather low 24 microHenries and there is no chance of reproducing a full frequency range. These lams look familiar – I have seen similar ones in Thiele microphones for the power transformer, and also, I think, in Geloso amplifiers

|

| Domed end cap of the mic, with striped output leads |

The maker, whoever he was, has used brass, mild and stainless steels, copper and aluminium for the construction. Parts are turned, milled, brazed, folded and domed. It looks more and more like an engineering workshop project designed to showcase the maximum number of skills, and in that respect it does a very good job.

Better laminations or a new transformer would show the true potential of this mic, as would some stronger magnets to boost the field. I will try that!

If anyone out there knows more about this mic, I would love to hear from you.

* Geologists often use their hammer in photographs as a way of denoting the scale of rock formations and features.