Tag: STC

STC 4136 revisited

|

| STC 4136 microphone |

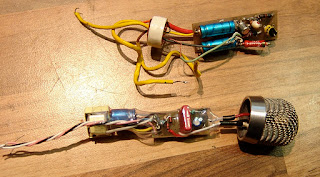

A long time ago I posted about the STC 4136 condenser microphone and how to modify it to work on standard 48V phantom power, using a small circuit built on perfboard.

|

|

|

I had another opportunity to work on one of these microphones. This one was a challenge as it had no circuit inside at all, just the capsule and bodywork, although that also gave free scope to start from scratch.

|

|

|

Space is tight in this microphone, but with a careful layout and small components everything will fit neatly. My solution for this one was to fit a small KM84 circuit and Neutrik NTE10/3 transformer. This transformer performs well, does not break the bank, and can be squeezed into tiny spaces where nothing else will go.

|

| New circuit board and transformer |

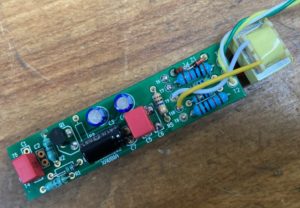

This time I commissioned a printed circuit board rather than working on perfboard, which does save time and look more professional. The board will be useful for other projects too – I have a handful of other small microphones which would benefit from updated, lower noise circuits.

|

| Made in England |

Thanks to Robert at Russell Technologies for the board layout and advice.

Repairing an STC 4033 with a cracked casting

The STC 4033 cardioid microphone was a stalwart of British broadcasting and an early solution to the the challenge of making a cardioid directional mic. The 4033 contains both dynamic and ribbon elements, and in cardioid mode the microphone blends the two transducers together via a capacitor and inductor – you can read more about the filter and switching circuit at the wonderful Coutant.org website. The mics are still quite popular with some recording engineers, but of course there are no spare parts available after half a century or so.

|

| Omni and Figure 8 suming to a cardioid pattern – from SOS website |

I was recently asked to repair a 4033 with a cracked bottom bell, which is made from some kind of zinc alloy. When I took the microphone apart it became clear that the casting had collapsed into several pieces, only held in place by the rest of the microphone. The job looks like a challenge, and we like a challenge.

It isn’t clear how this became so damaged but it is possible that the alloy itself was at fault. Zinc Pest is a notorious cause of failure caused by impurities in zinc alloys, particularly those from the 1930s and 1940s. Like this one.

The alloy is pretty much impossible to solder or weld back together, and I don’t believe that any glue would be strong enough to hold when the mic is bolted back together. A new part is required but impossible to find, so we need to make one, or at least persuade somebody else to make it. Metal casting requires specialist skills and equipment, so I asked Abbey Casting to copy a good part from another 4033, and they did a fantastic job to produce this part in bronze.

The raw casting needs various holes drilling and tapping, but with a little work we have a perfect fit.

The 4033 is not the easiest thing to work on – everything is tightly packaged and the transformer is set in wax into the stem of the mic, so I had to use a hot air gun to dismantle it. Whilst the mic is apart it makes sense to replace that Hunts capacitor* with a nice NOS Mullard, and re-solder all the old joints to lower noise and improve future reliability.

With the new part in place I can put it all back together again. The casting could be painted or powder-coated to match, but in this case the owner prefers to see the bronze. These are 50 ohm microphones and work nicely with our impedance matching transformer boxes.

Thanks to Liam at ToeRag Studios & Richard at Abbey Casting.

A mount for an STC 4017 dynamic mic

A customer asked me to make a mount for his STC 4017 dynamic mic without modifying the microphone itself. Often these come with a handle or a threaded stud for mounting, but this one came with nothing at all.

My first thought was to make some kind of ring clamp, but that would require a large diameter brass tube and was starting to look quite expensive and bulky. So I came up with this…

It is simply a folded strip of aluminium screwed to a threaded brass cylinder. The bass of the cylinder is threaded to fit a 5/8″ mic stand. The mic slides into a slot in the aluminium and is held by its own ground clamp.

Some shrink sleeve ensures that the signal outputs are not shorted by the new mount.

Voila!

Something old and something new – STC Coles 4038 and 4050

A good customer brought in his Coles 4050 stereo microphone for show-and-tell, which gave us a good opportunity to compare and contrast with some of the STC-Coles mics from the past.

|

| STC4033, 4038 and Coles 4050 microphones |

|

| Frequency sweeps of 4050 (top, red & yellow) and 4038 (bottom red) |

We ran a frequency plot of both halves of the 4050, and of the 4038.* Both mics sound very good, and although the old 4038 had a smoother top end roll off, the 4050 had an extended about +6 dB higher output and an extended frequency response. We were also very impressed with how well matched the two 4050 ribbons were – less than ±0.5dB across the range, and mostly much better than that.

The 4038 is prettier though!

* Taken at 30 cm distance. Please note that some of the bumps are due to our test chamber – there are issues with calibration when comparing a figure 8 ribbon with an omnidirection reference mic.

Thanks to John Gooding

STC 4136 condenser mic – phantom power

Here is a little curiosity. STC are mostly known for making high quality ribbon and dynamic mics, inclduing the much loved 4033 and 4038 models. But they also made condenser mics, and this nice little STC condenser mic came in for service recently….

It is model number 4136, and according to its specification sheet would originally have had its own power supply, which ran on either mains voltage or five 9 Volt batteries. Unfortunately the mic was bought without the power supply. The power would have been supplied to one pin of the XLR connector, ground to another, and (unbalanced) audio to the third. The capsule has a sintered glass, metallised backplate.

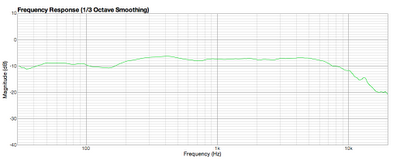

In practice, the conversion worked nicely, and despite its age and rough looks, the capsule gave a relatively even response, with a broadly cardioid pattern.

|

| Measured frequency response plot for STC 4136 |