Bang and Olufsen are a Danish company that make high end hi-fi equipment. Once upon a time they made some decent ribbon mics too. Here are a few…

|

| B&O ribbon mics, from left, 2x BM2, 2x BM3, 2x BM6, 3x BM5 stereo |

As far as I can tell, the first commercially available B&O ribbon mic was the BM2 – which begs the question “what happened to the BM1?” There seems to a bit of confusion about this, and possibly there never was a model called BM1. According to Beophile, the first B&O microphone was a dynamic mic called MD1. However, others have listed this as BM1. Numbers 2 to 7 were ribbons and carried the prefix BM, which may have stood for ‘baand mikrofon’ – Danish for ribbon microphone. Although it could also have stood for beomic. The MD8 was also a dynamic.

|

| B&O BM2 ribbon microphone |

Regardless of the BM1 (or lack thereof), the BM2 is a good-looking microphone, with a very different look to the later mics. It has a cast metal body and folded, chromed brass grill. The mics were painted in a green-yellow textured paint, which looks better than that sounds! They are usually* 50Ω mics, with an a switch which connects an inductor into the circuit, for a high pass filter. The ribbon is held in a removable frame, which slides out for servicing. (*They can be re-wound for 300Ω, to great effect).

The BM3 and BM4 look very similar to one another, and used an evolution of the motor assembly in the BM2, this time in conjunction with a steel tube body. This design set the style for all their later ribbon mics, and also inspired Speiden and Royer microphones, and a bunch of clones such as this Stellar mic.

|

| B&O BM3 microphones |

In the case of the BM3, the ribbon motor frame is larger than the diameter of the tube and sticks out from the sides of the mic, giving it the look of a long face with ears, or perhaps Doctor Who’s Cybermen. It has a three way selector switch which provides M (music – full range), T (talk – HPF) and 0 (off) positions.

|

| Motor frame from the BM3, with Xaudia transformer, awaiting a new ribbon |

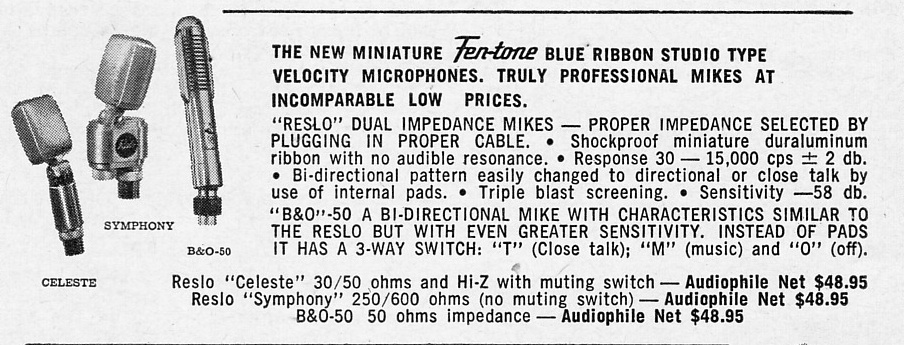

The BM4 looks the same as the the BM3, but with an additional switch at the rear for selecting 50, 250Ω, or high impedance output. The BM3s were fixed at 50Ω (and benefit from a matching transformer or upgrade). Occasionally you see these badged as “Fentone”, although, oddly enough, they kept the B&O name on the mic too.

|

| Fen-tone add showing the BM3 – from Preservation Sound |

The BM5, BM6 and BM7 came later and formed a family of mics. The BM5 is the stereo model, and when rotated to 90 degrees, it is perfect for Blumlein pair recordings. The bottom half of the BM5 was available separately as the mono BM6, and the top was called the BM7, although it could not be used by itself.

|

| Standard BM5 stereo set with stand |

The design was an evolution of the BM4, but by this point the ribbon frame and been replaced by plastic mounts, and the cyber-ears have gone. The magnets are also slimmed down, with a semicircular or triangular cut-out, presumably in an attempt to increase the high frequency response. In these mics the body of the mic is made from steel and also acts as the magnetic return path, which helps to increase the output.

|

| Insides of a B&O BM6 ribbon mic. Note the pistonic ribbon |

Like all of Bang and Olufsen ribbon mics, the BM5/6/7 family have a pistonic ribbon, which is gently curved in the middle and deeply corrugated at each end. The ribbons were made from Duralum alloy, which contains copper in addition to aluminium, to improve the strength and stiffness. However, the alloy is more prone to corrosion than pure aluminium, and it is quite rare to find ribbons that are in perfect condition.

|

| Delux BM5 set in posh wooden box! |

From a technician’s perspective, these later mics are less robust than the BM3/4. To me they feel more of a hi-fi design than one for a busy working studio. Although the sound is excellent, they are delicate in places and some of the plastic parts deteriorate with age, most noticeably the rotating ring in the top part of the mic. The switch tips also have a tendency to come off.

|

| Plug for a B&O BM3 microphone |

All the B&O mics used bespoke connectors, which can be hard to find. the BM2, 3 and 4 have a 3 pin connector only found on B&O equipment, whereas the BM5 and 6 used 5-pin DIN connectors but with their own threaded locking ring. The latter can be replaced with a standard bayonet DIN if the cable is missing.

Here are some links to wiring diagrams for some of the mics.

BM3 data sheet

BM4 data sheet

BM6 data sheet

BM7 data sheet

Thanks to Tom Day and Robin Kiszka-Kanowitz for additional information.

Update 1/2/18

Our friends at Extinct Audio now manufacture the BM9 studio ribbon microphone, which shows the influenced of the B&O designs.

Update 4/3/14

We now have upgrade magnets and transformers for all B&O microphones.

Update 22/4/13

Many thanks to Evan Lorden for sharing these photos of his B&O MD1.