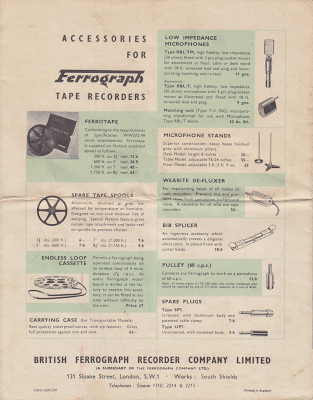

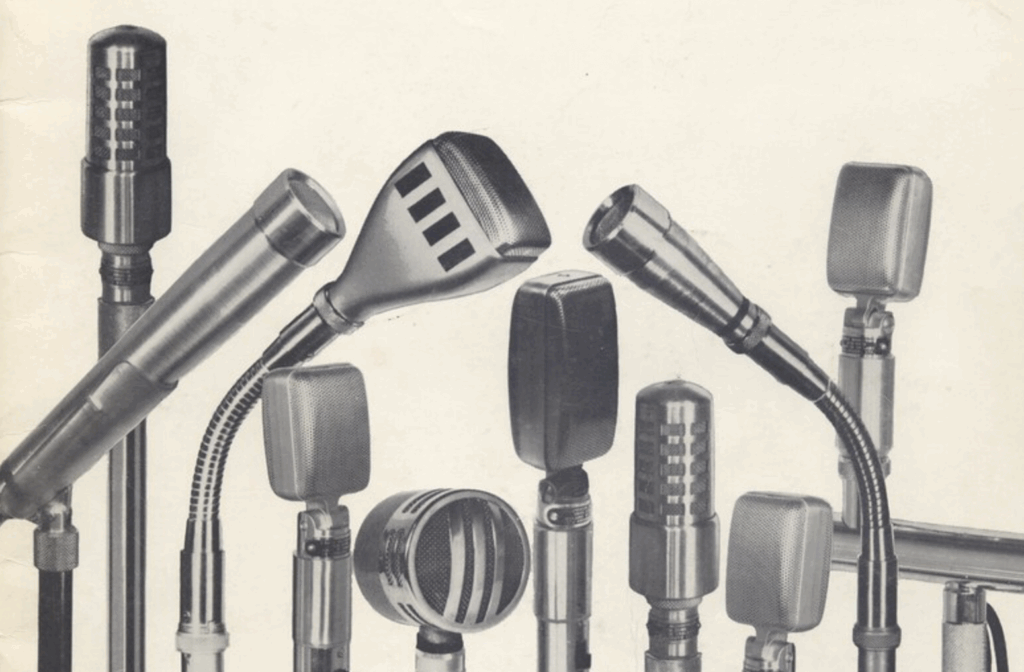

Reslo, a.k.a. Reslo (Sound) Ltd., a.k.a. Reslosound, was a British manufacturing company who made audio equipment and produced A LOT of microphones between about 1937 and 1978. In just 40 years they went from making primitive carbon button style mics through ribbons to modern looking electrets and handheld dynamics. In the middle were the ribbons that we associate with the brand, including the RB and CR models used by a well-known beat band from Liverpool. 🙂

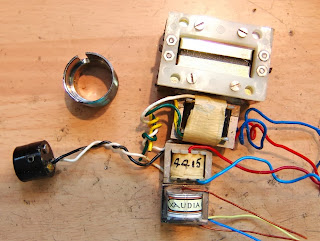

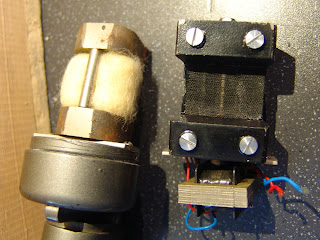

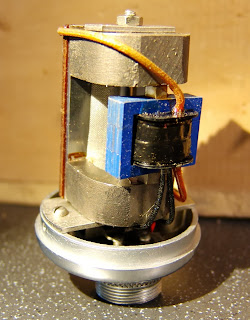

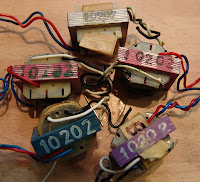

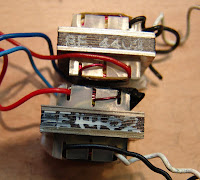

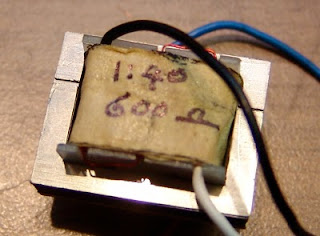

Reslo mics are by far the most popular brand that we see in for service at the Xaudia workshop, and I probably work on a hundred or more Reslo mics each year. The RB model is the commonest, making up perhaps 90% of those that come in for repair or for our popular Beeb (BBC) upgrades.

Although we have good documentation for many of these microphones, most of the original manuals and promotional material are undated, so we have to work a bit harder to find dates for Reslo products.

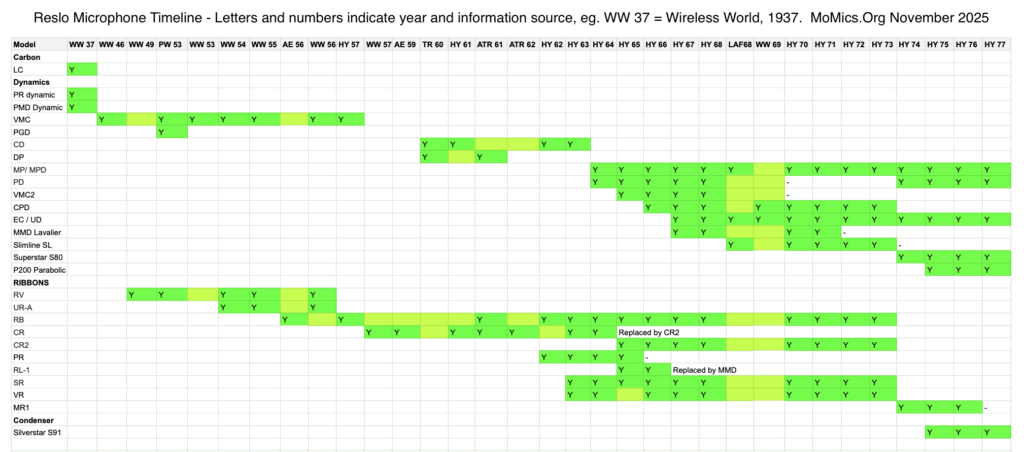

I have attempted to summarise when the Reslo models were made by trawling through numerous old magazines, looking for advertisements and reviews. The nice thing about magazines is that the issues usually have dates, which gives us a snapshot of which microphones were available at that point in time. Wireless World and HiFi Yearbook proved especially helpful.* The results are in the spreadsheet below – we may have missed a year or two either side, but these dates are broadly accurate to the best of my knowledge. Information before about 1960 is scarce and should be considered less reliable than that for later models, and we have almost nothing from the wartime years from 1939 to 1945. Additional documents may come to light in the future which can expand our time line. Let’s hope so!

The earliest models appeared around 1937 and include the LC, a carbon mic, and two dynamics, the PR** and PMD. By 1946, with a world war in between, these three models have vanished and the VMC dynamic mic has appeared.

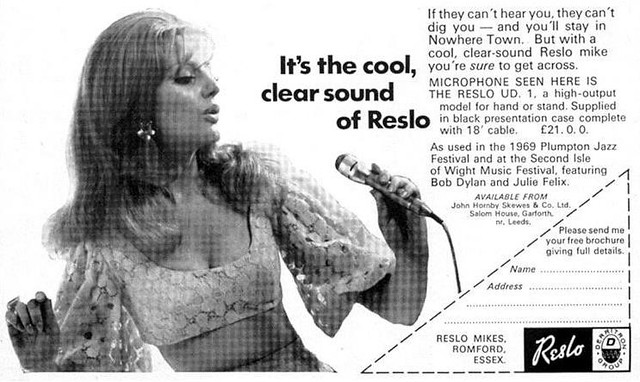

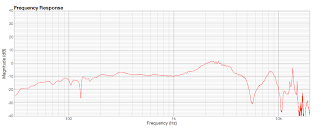

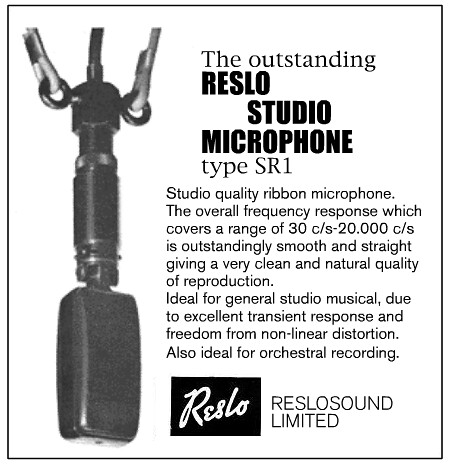

We can see that the RV ribbon microphone was available from around 1949 through to the mid 1950s, when it was superseded by the hugely successful RB and related models (including the SR1 and VR), which were in production until 1973. The end-address CR model (which is really just an RB in a different shell) was launched around 1959 and received a face-lift in 1965 to become the CR2. Amazingly, the VMC and VMC2 dynamic microphones were in production right up to 1968, by which point these heavy paper cone dynamics were very old technology and sonically no match for an imported shiny new Shure or Neumann!

In hindsight, 1973 looks like a year of revolution at Reslosound, with many of the old models, including the RB and CR series, being retried. Several new dynamic models were launched, along with a new logo and even an electret condenser for the first time. The only ribbon microphone left in the 1974 line-up was the MR1, which used a repackaged RB motor with a smaller transformer. I surmise that they were trying to modernise their range to compete with imported mics from Germany and the USA.

But it didn’t work. Sadly, by 1978 Reslo had ceased to exist.

*World Radio History website is an invaluable resource for searching old audio publications.

** They later recycled the PR name for the Pencil Ribbon which appeared around 1962.

Thanks to Sam Fitzgerald Kay and Marco van der Hoeven for their help in compiling this information.