I have been thinking for some time about a stereo guitar that would spread out the signals from the different strings to a pair of amplifiers, or to stereo inputs for recording. So here is my first attempt at winding a stereo pickup.

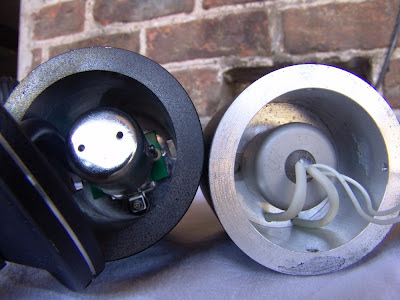

In order to get some separation between the strings, I decided to make six mini-pickups and combine them into sets of three. Here are the parts – six bobbins, six steel pole pieces, an Alnico 5 bar magnet, and a home made top board.

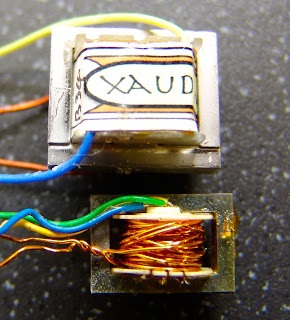

Each was a coil of 5000 turns 42 AWG enamel wire, around a steel bar. Three of the coils were wound normally and three reverse-wound as they will sit on magnets of reverse polarity.

|

| Winding mini-pickups on the Meteor winder |

These were then arranged in two sets of three, magnetised by a bare of Alnico 5. The hard part is keeping track of the winding direction, the start and end of the wires, and the magnet polarity – so that everything is in phase! Each set of three coils were wired in series, and the E,D & B strings sent to one output, and A,G & E sent to the other. Once done, the parts were glued in place, soldered, and then dipped in the wax bath.

|

| Assembled six-coil pickup with magnet |

And then it was mounted in the test guitar – my trusty Reverend Slingshot, with the pickup simply taped in place for a test run. The next job is to mount it properly and put a cover on to hide the mess – the hard bit was finding an undrilled P90 cover, but ebay came to the rescue.

|

| Reverend Slingshot with prototype stereo pickup |

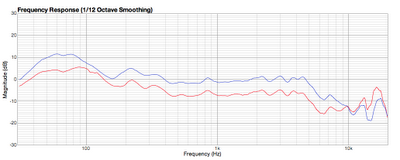

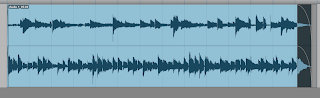

So, how does it sound? Here is a little run on the guitar and the screenshot from protools. The recording was made into the instrument input of an API A2D, using the digital output at 24bit, 96 kHz into protools. Then no further processing, other than bouncing to 44.1 kHz, 16 bit.

[The stereo image of laptop speakers is usually pretty awful, so best checked out on headphones!]

…mp3 version…

As always, the stereo is much better on the .Wav version (5 mb…)

The isolation between the two sets of strings is actually very good – you can hear and see on the screen shot that the two channels are very different, following the two sets of strings. It gives a nice interesting stereo spread with the run on the B-string being panned to the right, and the lower notes played on the A string going left.

Another stereo example is here, along with the separate left and right components.

I imagine this would be good for double tracked guitars with big Pete Townsend style chords – using two amps. Although this is wired for stereo, it could easily be made into a hexaphonic* pickup. I’m not sure what use that would be in the real world, but it would certainly be fun to find out.

Update: Here is the pickup mounted properly in the Reverend guitar

Footnote

*The concept of a hexaphonic pickup is by no means new. The earliest patent reference that I could find to the word ‘hexaphonic’ is in this application by Gibson filed in 1990. This refers to midi pickups and states “The first category usually makes use of a special pickup which is mounted on a normal guitar as is the case in the present invention It is deemed important to retain the guitarness or feel of the instrument and a retrofittable hexaphonic magnetic pickup is utilized….” So the idea of hexaphonic pickups was well understood by that point, and in fact must have been obvious even to the very first pickup winders.

Digging deeper I found this article on polyphonic pickups, in Premier Guitar magazine, which covers the subject in better detail than I ever could.

And here is a story from the Gretsch website about Chet Atkin’s stereo guitar from 1956, which used a split coil to send the three bass strings to one side, and the three treble strings to the other. They applied for patent in 1956, and this was granted in 1960.