This little dinosaur sculpture was made out of waste winding coils, stripped mostly from old Reslo and other microphone transformers. 🙂

So why are we stripping transformer coils?

Some older ribbon mics were originally wound for 30 or 50 ohm output impedance, and tend to give a low output level when connected to modern recording equipment.

Many of these low impedance mics, including Reslo and Tannoy ribbons, can be rewound for a modern 200 or 600 ohm input, raising the output to a more useable level, and avoiding noise from having to crank up the preamps.

|

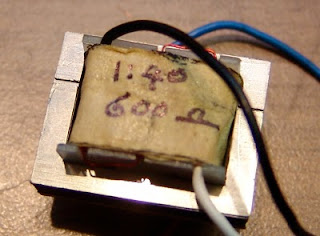

| Bobbin from Reslo transformer with secondary winding removed. |

The old Relso 30/50 ohm transformers have an inner (primary) winding consisting of just 12 or 13 turns of thick (0.8 mm) enamelled wire, and a secondary winding of 152 turns of 0.4 mm wire. The thick wire of the inner winding ensures that the primary resistance is low, which keeps noise to a minimum.

|

| Reslo transformer rewound for 600 ohm output |

Re-winding the transformer involves removing the outer winding from the original transformer and replacing it with sufficient turns of a thinner gauge to reach the desired turns ratio and output impedance. Usually the original primary winding can be kept in place. The transformer is then reassembled and dipped in wax to fix the windings and lams in place.

This makes the microphone much more usable in a modern studio – transformers can be would for 250Ω, 600Ω or any other desired output impedance.