Tannoy’s Cardioid ribbon microphones

As well as the bi-directional microphones described in my previous post, Tannoy also produced several cardioid models. In the picture below,

the mic on the left is the MD422. I don’t have a model number for the centre and right hand microphones, but they are the same basic microphone inside, with very different grills and bodies.

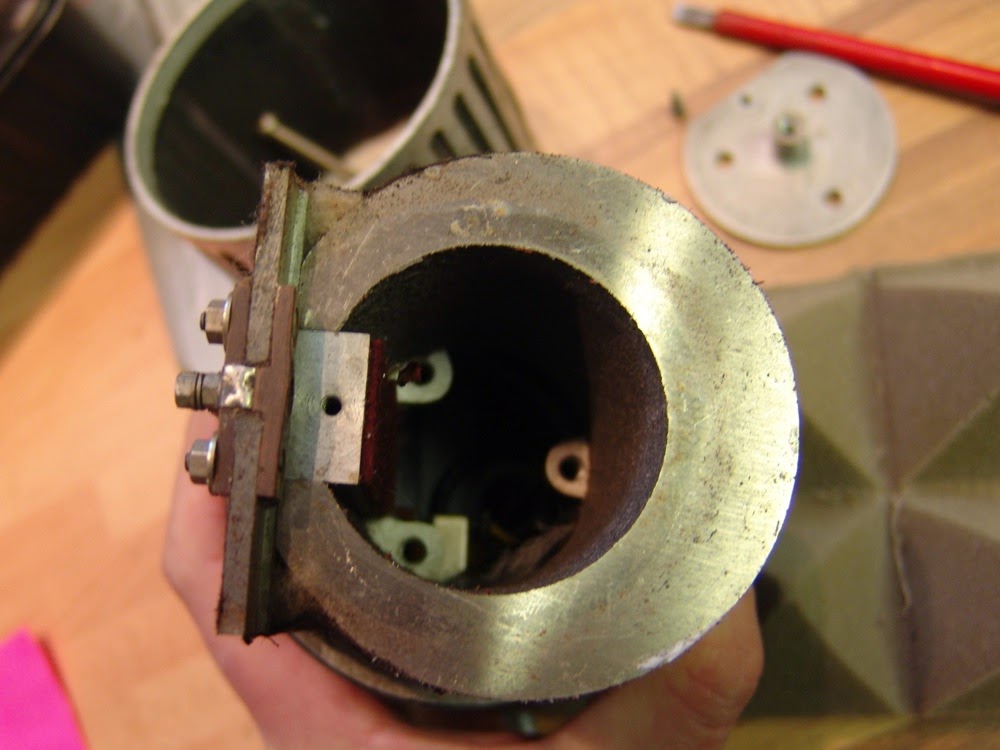

The internal design of these two microphones is very simple, with a huge heavy horseshoe magnet providing both the magnetic field and creating an internal cavity to help control the pattern. The ribbon pole pieces are simple rectangular steel plates screwed into position.

There is a layer of felt behind the ribbon. I also expected to see the cavity behind the ribbon stuffed with horse-hair or cotton wadding, but in this example it was completely empty. There is a small transformer in the base of the microphone – in this example the output impedance was 2000 ohms, but I’m sure that other output options would have been available.

Despite the size, the output level is rather low.

The MD422 uses the same ribbon motor as the

Type 2 bidirectional mic, and we can safely assume that they were contemporary models.

As well as these large cardioid microphones, Tannoy also produced this smaller directional model which looks rather like a dynamic mic:

The motor inside this mic is reminiscent of that from the STC 4104 lip microphone. It uses the same base and connector as the MD422 and MR425 models.

Update March 8th 2015Tannoy were developing directional ribbon microphones from the mid 1930s onwards. I have never seen this model on the bench, but this sketch appears in Wireless world in September 1937:

Tannoy and the Houses of Parliament

Here’s the problem: I have seen several of these brass-barrel Tannoy mics on sale that claim to be ex-Parliament. Too many, certainly more than twelve, and some at very inflated prices. Either Parliament kept a huge number of spares (which is possible, I guess), or this model was not exclusive, and was sold elsewhere. I have heard anecdotally of these being salvaged from church PA systems, and also the Canadian government.

Additionally, I have seen, and bought,

Type 3 bidirectional Tannoy mics that claimed to be ex-HOP., although when I asked for documentation as proof of the claim, the seller was unwilling or unable to do so. Were these fitted in the 1970’s refurbishment? Again, it is possible, but I have yet to see any proof of this claim. If you know better than please get in touch and show me!

The lesson here, as always, is Caveat Emptor, particularly when buying used microphones.

Update March 8th 2015

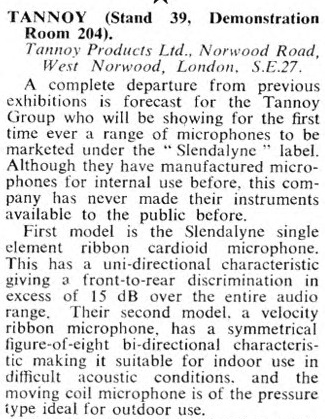

Thanks to one of our readers for sending in a link to this announcement in Tape Recording magazine (1962, issue 5). This adds to the Houses of Parliament microphone debate.

The article announces two new ‘Slendalyne’ ribbon microphones from Tannoy – a cardioid and a bidirectional version. Yet the cardioid version looks very much like the brass-barrel mic that was supposedly installed into the Houses of Parliament 11 years earlier! This sentence is particularly intriguing: ‘Although they have manufactured microphones for internal use before, this company has never made their instruments available to the public before‘. The statement is not quite true as their earlier models were widely available. But this implies that these specific models had previously been supplied to select customers, and became available widely from 1962 onwards.

……………..

Thanks to Tom McCluskie, Jamie Neale of

Real World Studios, and Marco van der Hoeven of

Vintage Mic World, and everyone else for sharing information and photographs of their microphones.