The Xaudia Blog

MOTM – Toshiba ribbon mic

|

| Small Toshiba Ribbon mic |

Toshiba are better known these days as a giant manufacturer of consumer electronics goods, so it is perhaps surprising to find a ribbon microphone with their name on. In fact back in the 1960s Toshiba made some pretty decent models, some of which were good copies of RCA mics.

February’s microphone of the month is this little ribbon mic, which lacks a model number, but has been referred to as an RCA74b clone. However, although from the outside it resembles a smaller 74b, inside it is very different.

Beneath the outer grills lies a perforated metal baffle backed by a finer mesh screen, which protects the full length of the ribbon against air blasts and pops. The top and bottom of the shield have a tendency to go ‘ping’ – I could actually hear this ringing when speaking into the mic, so a little bit of sticky foam was used to damp this.

|

| Rear of the Toshiba showing transformer and magnets |

From the rear, we can see that the field is suppled by a pair of strong horseshoe magnets glued to the pole pieces, which give a measured field of about 3000 Gauss between the poles. The transformer is a twin core ‘humbucking’ type, in this case wound for high impedance.

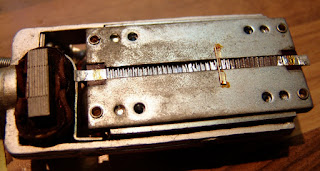

Once the inner screen is removed, two features stand out as unusual. Firstly, there are no ribbon clamps! The ribbon is simply glued to the supports, and then soldered to the terminals. The arrangement works well enough, but you only get one go at fixing the ribbon.

|

| Toshiba ribbon |

The second interesting thing is the small cross bar that bridges the pole pieces. This is actually glued to both the pole pieces and the ribbon itself, dividing the 3.6 mm wide, 60 mm long ribbon into two sections in a 3:2 ratio. I can imagine two purposes for this – to stop the long thin ribbon from travelling to far, and to minimise overtones from harmonic motion.

I have also seen this ‘node’ on another Toshiba ribbon model, so it does seem like a little trick of theirs. The nearest thing I have seen in other microphones is in the Cadenza mics, where the ribbon is glued to a support half way along.

|

| Microphone cleaning |

This mic was rather dirty inside. Lots of little bits of iron were interfering with the ribbons movement, making it sound like it was scraping against the sides – which it was! These were easily cleaned with some sticky tape, but the ribbon had to be sacrificed first.

|

| New ribbon in the Toshiba mic |

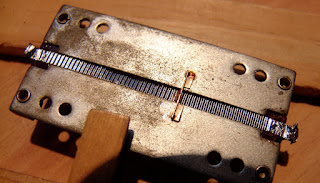

A new ribbon was fitted – soldering 1.8 μm aluminium foil is a bit tricky, but I got the hang of it after a couple of tries. And gluing the cross bar to the ribbon also requires a steady hand!

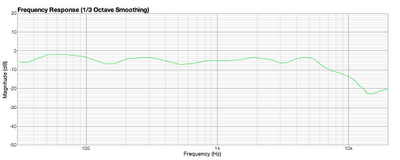

Once re-ribboned and reassembled (and fitted with a low impedance transformer), the microphone sounds nice, with a relatively flat response up to around 6KHz, where it begins to roll away.

|

| Frequency plot for Toshiba ribbon mic at 35 cm. |

‘Yorkshire Tour’ Stratocaster pickups

I spent Saturday helping my former band-mate Ant make new pickups for his 1983 Fender Stratocaster – the stock pickups were OK but lacked a little warmth, and he wanted something overwound (i.e. more turns than a ‘standard’ strat pickup), to give a hotter, fatter sound inspired by Rory Gallagher’s ‘Irish Tour’ album.

|

| Ant makes single coil pickup formers from board and magnets. |

Magnetic fields fall away rapidly with distance, and with a moulded plastic bobbin, there is inevitably a gap between the pole piece and the coil. Instead, we made the pickups in the traditional manner, with board and Alnico-V magnets supplied by the mighty StewMac.com. Although it takes a little time to construct the pickup in this manner, this method does give a better sound, as the copper wire coil is wound directly onto the magnets, with the most intimate contact possible.

| The old strat pickup assembly removed |

We made a couple of small tools to help with the assembly. A pair of acrylic blocks were cut to act as spacers between the top and bottom of the pickup, to keep the boards parallel. One of these was drilled to help align the magnets as they were knocked into place. The other tool was a spindle for the coil winder.

|

| Knocking in the magnets – a strip of wood protects the magnet from the hammer! |

Once the three bobbins are assembled and glued, it is a simple case of winding the required number of turns onto the former without breaking the wire! The neck and mid pickups were wound with 9000 turns of 42 AWG plain enamel copper wire, and the bridge pickup with 9800 turns, which gave DC resistances of 6.7 kΩ and 7.4 kΩ respectively. 7.4kΩ indicates that around 1300 meters of wire has been wound onto the pickup! For comparison, according to Vintage Guitars Info, the original Stratocaster pickups measured circa 5.8 kΩ to 6.3 kΩ.

|

| An assembled pickup – magnets and flatwork – on the coil winder. |

It was interesting to see how the original pickups were wound – they are pretty inconsistent, and one in particular had substantial asymmetry to the coil. Perhaps there is some magic to this, but we suspect that it was just their winder drifting out of alignment and piling up the wire on one side.

| Fender Stratocaster pickup, circa 1983. |

Our pickups were a bit neater than that! Once wound, the lead wires are soldered on, and the complete pickups are dipped in the wax bath to stop microphonics, and then magnetised. A pair of very powerful 1 inch circular neodynium magnets were used to magnetise the Alnico 5 pole pieces, and we measured around 900 to 1100 gauss for each of the poles. The middle pickup was reverse wound, and given a reverse polarity, by simply flipping the bobbin over for the winding and magnetisation processes. This gives some humbucking when the mid-positions are selected.

The verdict? “Those pickups are PHAT!! Awesome. Loads more bass!“

|

| Back together again – Stratocaster heaven! |

Melodium 42B Stand Adapters

Xaudia is pleased to announce this little gadget…

|

| Melodium 42B stand adapter |

Anyone who has ever tried to put a Melodium 42B on a mic stand knows that it is challenge, if the original adapter is missing – which it often is.

|

| Melodium 42B with Xaudia stand adapter |

The Melodium 42B can now be securely mounted on a stand. Problem solved!

Altec 438C compressor amplifier

The Altec 436 and 438 series are vari-μ tube compressor-amplifiers that were famously used at Abbey Road in the 1960s, when the Beatles were there. The 438C is the best of these models, in that it has a built in mic preamp, and also control of the threshold and release, which make the compressor a lot more usable.

I have been looking for one of these for some years now, to the extent that I even built one from scratch – but of course without the gorgeous meter. I finally took the plunge and bought this one on US ebay, for (what I considered to be) a fair price.

|

| Altec 438C compressor |

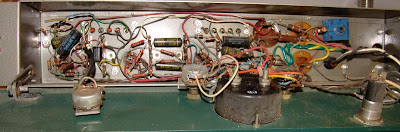

Having paid the ransom to release it from customs, I picked it up from Parcel Force today. Happily, it looks to be in good original condition, and it should not be too much of a challenge to get it up and running again.

There is plenty of vintage dust inside…

|

| Inside the Altec 438C compressor |

A few things will need to be done. These were built for the US market, and the transformer will need to be swapped to a 240V model. It would also be prudent to swap out the electrolytic capacitors. All the original transformers are present, which is a relief as these are difficult / expensive to find.

The ‘clone’ has been in regular use for years, and it will be interesting to see how the original compares!

|

| Home made 438B compressor |

Making a spindle for winding pickups

Next week we will be making a few single coil pickups for Stratocasters, so I quickly made this simple little spindle tool to help with the job. It was machined this from 15 mm brass stock on the new mini-lathe, which arrived earlier this week. Below is the roughly machined spindle, before cleaning.

The pickup bobbin slips onto the 3mm post, supported by the wide shoulder, and is locked in place by a square of flatwork board, screwed into the side. This prevents the pickup from slipping on the spindle, without interfering with the wire as it is wound on. The barrel was turned down to 8 mm to fit the Meteor coil winder, although it could equally well be used on a power drill chuck.

SC2 Mini-lathe

The mini-lathe is here!

Delivery was a little late due to the snow and ice, but it finally arrived on Tuesday. After unpacking and cleaning off the excessive quantities of grease, I made a couple of quick jobs as part of the learning curve – the best way to learn is by doing, even if it involves a few mistakes.

First up was to machine this little spindle to hold bobbins for the coil winder. The spindle is in two parts, and is made from 10mm diameter aluminium rod. The lathe is very handy for making little tools like this.

Then I used the lathe to replace the broken connector on this B&O microphone. The old connector was cut off, the hole widened and threaded to take an XLR output. Finally I can get this mic up and running! 🙂

|

| B&O BM3 with XLR output |

The lathe is a useful addition to the workshop, and is already proving its worth. It needs a few tweaks to set it up and take some of the slack out of the slides. Luckily, mini-lathe.com have excellent information and guides to setting up these machines.

Grampian GR1 XLR conversion

At Xaudia, one of the most common enquiries that we get is for replacement cables and connectors for vintage microphones. Very often we can help, but some of the connectors are becoming impossible to find in good condition and at reasonable prices.

One example is the Grampian plug that was used for their GR1 ribbon and other microphones. These connectors are hard to find – they can be obtained by buying a less valuable Grampian dynamic mic, but we have found that the plugs come with various slightly different threads, which means that one plug cannot be guaranteed to fit another microphone. And the connector is not ideal in the first place – it has two prongs and for balanced use the screen of the cable is connected to the plug casing (and therefore the microphone) by pressure only. Grounding issues are therefore common.

There is, however, another approach, which is to dispense with the connector entirely, and replace it with a modern, industry standard XLR connector. This microphone arrived without a plug and with a rather battered and bent connector at the bottom of the mic.

The decision was made to replace it with a silver-plated XLR output, which also solves any grounding issues as the third pin may be connected to the body of the mic.

The old connector was cut off, and the housing threaded to accept the new connector.

The new XLR output is then simply screwed in place… and the mic rewired and put back together.

|

| XLR modified Grampian |

Everything works nicely – just plug a standard XLR mic cable and it is ready to record.

Some may see this as vandalism, and perhaps from a collectors point of view, it is. However, the conversion is sympathetic, and it is far better for the mic to be making recordings, than to be languishing in a box unused.

Bang and Olufsen BM2 microphone

Last month we were lucky enough to see this rare and beautiful B&O BM2 microphone pass through the workshop.

According to the BeoPhile.com website, these were made from 1951, and was replaced by the very different looking BM3 in 1962. Although different in appearance, the motor assembly and ribbon are similar in both cases.

The BM2 also has a switchable high pass filter to select between the music and voice modes, and also shares a hard-to-find connector with the BM3 & BM4.

Beyond that, we don’t know a whole lot about it!

Reslo wiring guide

This is the ‘official’ wiring information from the Reslo RB brochure…

As you can see, different models had different wiring conventions and required different colour coded cables. This can cause confusion, particularly if the mic has been separated from its original cable in the 40 or so years since manufacture. The most important thing is to check the mic and cable wiring and make sure that they match!

Unfortunately, grounding the mic by connecting the cable screen to the body of the plug does not work well, and these mics are prone to hum. For the low impedance models, it seems sensible to use pins A and B for the balanced output, and pin C for ground. The ground must also be connected to somewhere to the body of the mic and/or to the shell of the cable.

The dual impedance models are particularly problematic, in that pins B and C were used to select either low or high impedance output. This means that if one pin is used as a ground then one part of the transformer will be grounded and some of the signal lost. It is therefore important to disconnect the high impedance leg inside the mic and rewire to match the cable.