|

| RSA Selmer RL1 microphones |

So what’s in a name? Some of these microphones have two manufacturers’ names on them: RSA is proudly embossed on the aluminium body of the mic, whereas the switch plate reads ‘Type RL1, H. Selmer & Co. Ltd., London, Made in England”. Others have RSA on the switch plate too, although these seem to be less common, and I have only come across one example of this.

According to the Vintage Hofner website, Selmer took over the R.S. Amplifiers Ltd in 1947, and presumably these schizophrenic examples come from around that time, when the new owners were using up the cast casings. They are are made from a big slab cast aluminium, with a chrome grill. They are mounted by a yoke with a switch in the base, and the black paint with bare aluminium stripes gives it a very distinctive Bauhaus* / Art Deco appearance.

|

| Inside the RCA Selmer RL1 microphone |

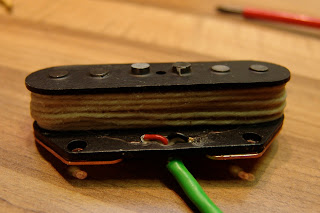

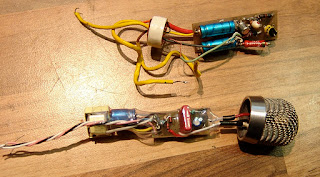

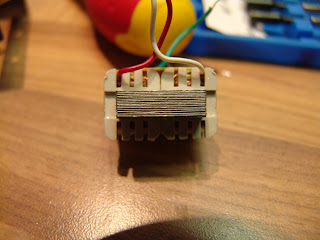

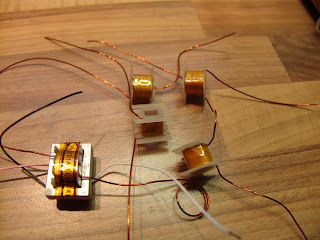

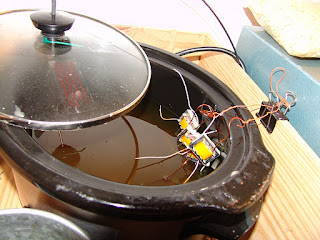

The main body of the mic contains the ribbon motor assembly, hidden inside a cotton bag, and a large iron core transformer with a very thick double (parallel) primary winding. The secondary winding connects to a short length of cable, which goes off to the switch.

One thing to note about these mics is that many of them are designed for a very low impedance. The relatively thick piston style ribbon and low ratio transformer combine to give an output impedance of around 15 ohms (measured at 1kHz), and so they can seem very weak when plugged into a modern preamp. In this case a matching transformer is essential to get a decent level from the mic.

Also, these mics do not generally have a secure earth connections, and may hum unless one is provided. Fortunately, it is a simple job to add a terminal to the inside of the body.

|

| Piston style corrugated ribbon. |

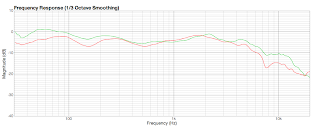

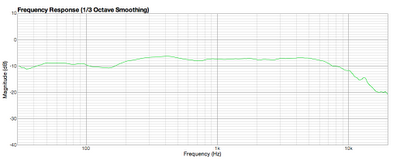

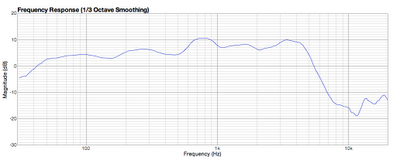

In terms of sound, these have a very vintage tone and limited bandwidth, rolling off rapidly above around 4kHz – perfect for an old AM radio broadcast effect.

|

| RSA RL1 frequency plot |

The RL1 was eventually replaced by the fully Selmer-ised RL2, which used the same grill insert. The RL2 seems to be a very rare thing indeed.

|

| Selmer RL2, from Vintage Hofner website |

* The design school, rather than the goth band. Although either might apply.