|

| Big old German bottle microphone (flaschenmikrofon) |

This time-capsule condition, stunning bottle mic is a recent ebay find, but we know very little about it! So, if you recognise this one, or have any further information, please get in touch.

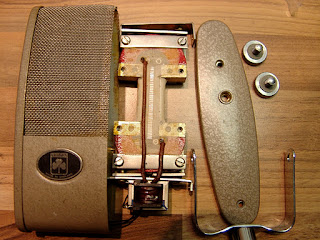

In looks, this is very much in the style of an RFT CM7049 or a Neumann CMV3, but doesn’t match any of the models that I am aware of by those manufacturers. The mic stands around 320 mm tall by 80 mm diameter, and is beautifully machined from aluminium, so we’ll call him ‘Big Al’.

The bottom bell is secured by two thumbnuts, which make access to the tube and battery compartment very easy.

The capsule is held in place by a clamping ring with 12 screws, and the diaphragm looks to be either nickel, or some kind of metallised film. It is not possible to get the capsule out of the head without removing these screws – not something I really want to be doing. It is even possible to work out the backplate hole pattern from the dents in the diaphragm.

|

| Bottle microphone capsule |

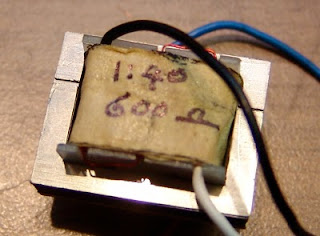

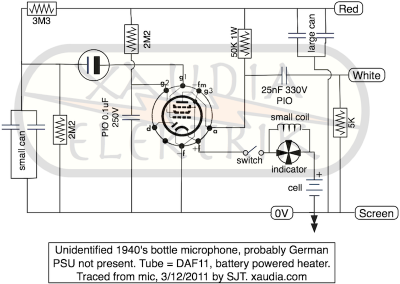

The tube is a Telefunken DAF11 which dates back to the 1940s. I haven’t met one of these before, but the datasheet is available at Frank’s, and shows it to be a diode and pentode in the same shell, with a common heater & cathode.

|

| DAF11 tube |

The diode part is not used in this mic. The heater supply is a modest 1.2V at 50 mA, and is designed to run from a battery cell.

|

| DAF11 bottle mic schematic |