Disclaimer

Firstly let me say that this is a study in progress, and should by no means be taken as definitive. Hopefully we will eventually have a big enough data set to be able to speak with confidence, but it will take a while!

|

| Red and black badges on Reslo ribbon mics. |

Are black label Reslos better, or even different from red ones?

There is a rumour that occasionally appears on the internet concerning the relative merits of Reslosound RB microphones. Some of the mics have red labels, and others have black ones, which has led to speculation that the mics must be different, and one type must sound better than the other.

Normally it is stated that the black badged ones are better. Most rumours have some basis in fact, so let’s investigate!

|

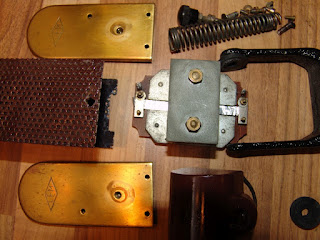

| Reslosound RB microphone dissected |

Over the past couple of years I have serviced around 50 Reslo mics, with both colours of badges. Here are some of my empirical observations…

1. The black ones are less common than the red ones, but they are by no means rare. I don’t have exact figures but perhaps 75% are red, and 25% black. I will be keeping note from now on!

Edit 29/11/2013: I wanted to correct this figure as I have seen it regurgitated on ebay a couple of times. Having seen a hundred or so more since I wrote this, I really can’t say that one is more rare than the other. I would probably guess that they are equally common.

2. There are at least three styles of red badges from different periods.

3. Some later mics (red and black) have a white plastic ribbon holder. The older mics have black bakelite holders. This should not affect the sound.

4. The transformers vary greatly in both looks and specs. This will affect the sound!

So, the only real differences between the red and black label microphones are the transformers (and possibly the state of the ribbons).

Recently, I had seven 30/50 ohm Reslo RB microphones on the bench, and I took the opportunity to examine the transformers. Although the basic construction is the same, the transformers are quite different in looks, and have different inductance values! Some have a striped core with two metals, the middle often being darker or rusty, suggesting a higher iron content.

|

| Reslo transformers (left to right) A, B, D, E, F |

Impedance and resistance values

This is hardly a statistically significant data set, but here goes…

Black labels

A. Lp = 0.463 mH, Rp = 84 mΩ, Ratio = 1:12, fc = 103 Hz (purple)

B. Lp = 0.434 mH, Rp = 56 mΩ, Ratio = 1:12, fc = 110 Hz (pink)

C. Lp = 0.470 mH, Rp = 56 mΩ, Ratio = 1:12, fc = 102Hz

H. Lp = 0.514 mH, Rp = 52 mΩ, Ratio = 1:12, (purple)

I. Lp = 0.441 mH, Rp = 45 mΩ, Ratio = 1:12, (pink)

Red Labels

D. Lp = 0.533 mH, Rp = 52 mΩ, Ratio = 1:12, fc = 89 Hz

E. Lp = 0.204 mH, Rp = 63 mΩ, Ratio = 1:13, fc = 234 Hz

F. Lp = 0.214 mH, Rp = 63 mΩ, Ratio = 1:13, fc = 223 Hz

G. Lp = 0.454 mH, Rp = 49 mΩ, Ratio = 1:12, fc = 105 Hz

Where Lp is the inductance at 1KHz, and Rp the DC resistance of the primary winding.

The mics are supposed to be 30 to 50 ohms output, and so from the ratio we can estimate the impedance of the ribbon and transformer itself to be around 0.3 ohms. The ribbon impedance and transformer inductance form a high pass filter, and so we can calculate the frequency, fc, at which the bottom end response drops away.* This handy tool means that we don’t have to get out our calculators.

* It must be noted that the inductance of a metal core rises and frequency drops, so the cut-off frequencies will in reality be somewhat lower than these values. However, they should be comparable to one another.

What we can say for now, from our very limited data set, is that the three black label transformers, and two of the red ones, have substantially higher inductances and lower cut-off frequencies than the other two red ones. This difference in bass response is likely to be what some users hear as ‘better’. However, it cannot be said that a red label mic always has less bass response than a black one.

The two transformers with purple paint have higher values than the ones with pink paint!

My feeling is that the later Reslos have ‘better’ transformers than the early mics, and that the colour is more cosmetic than diagnostic. But I shall keep adding to this list as more Reslos come into the workshop, and it will be interesting to see what trends develop.

And finally, if you are reading this and once worked for Reslo (or Grampian), we would love to hear from you.

Update 12 May 2012…

In 1961 the BBC R&D group studied the Reslosound RB microphone and recommended that the transformer be replaced with one of higher inductance. It seems plausible that the later Reslos were revised to use a different transformer following that study. You can read the BBC report here.

Stewart Tavener, Xaudia, First posted 24 April 2012, Latest update 12 May 2012