Here is Tannoy’s cardioid ribbon microphone – the MD422.

|

| Tannoy MD422 ribbon mic, front |

Firstly, Tannoy lose a point for the name. ‘MD’ should surely mean “microphone dynamic” in any sensible society! Perhaps the D stands for “directional”? Who knows, but it puts them at odds with other the Sennheiser MD421, and it is just plain confusing.

|

| Tannoy MD422 ribbon mic, rear |

Whatever the D stands for, the mic itself has an industrial look, and this one is finished in a bronze-ish coloured paint. To the best of my knowledge this is the only cardioid ribbon model that Tannoy ever produced, and it uses an acoustic labyrinth to provide the necessary back pressure to the rear of the ribbon. The chamber is the black cylinder in the photo below.

|

| Tannoy MD422 ribbon mic, chamber |

Some of the parts were made to a budget, or perhaps a short production run, with thin stamped metal for the base and top cap, along with two layers of off-the-shelf mesh to protect the mic from dirt and wind.

The ribbon assembly and magnets are the same as found in the type 2 Tannoy ‘pitchfork’ microphone, which would have saved costs by sharing components.

|

| Tannoy MD422 inside, showing ribbon motor |

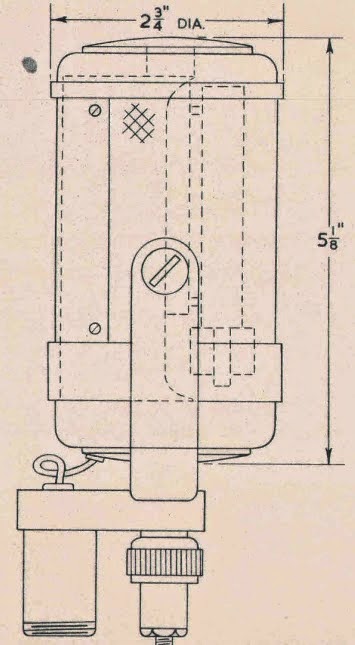

The MD422 was subject of a BBC technical report, which concluded:”..this microphone has nothing to commend it for use in the Television Service“. That assessment seems rather harsh, but at the time the Corporation’s selection criteria were flat, uncoloured responses and good signal/noise performance.

In the report, the bi-directional BBC-Marconi AXBT was used as a comparison, which was much more expensive, a different pattern, and therefore a tough benchmark. Cardioid (and non-directional) ribbon mics generally use an acoustic chamber on one side of the ribbon to apply pressure, and this damps the ribbon motion, reducing the output compared with its natural bi-directional response.

|

| Drawing of the Tannoy MD422 from BBC technical document. |

Unlike my mic, the BBC’s example had a yoke mount rather than a fixed base, although there are mounting screw holes in the side of mine.

Despite my irritation with the model number, and the BBCs damning assessment, I like this microphone very much. It has a gentle warm tone. More importantly, it was an attempt at technical innovation, which is always to be celebrated.